Rifles and rifle scopes have come a long way in the last few decades. The way shooters mount and use their rifle scopes has also significantly changed as new technologies have altered the industry.

One of the biggest changes has been the adoption of the quick detach scope mount by many shooters.

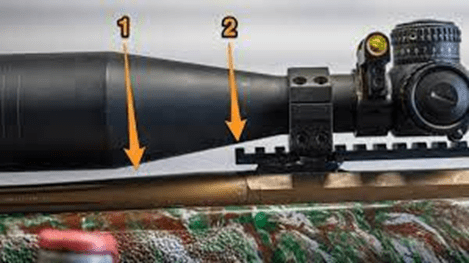

Scope mounts are the interface between your optical sight and your rifle. This important application requires tight tolerances, secure fits, and proper alignment to ensure a stable and reliable aiming system. For many years the standard scope mounts required drilling and tapping a rifle receiver.

The advent of the Weaver and Picatinny rails fundamentally changed the mounting system used by many shooters.

Traditionally, once a scope was mounted on a rifle, it was very rarely removed. In essence, the scope and rifle quickly became a single entity, never to be parted. Standard practice was to purchase a scope for every rifle in your arsenal.

While many shooters still follow this tradition, more and more shooters are opting to use quick detach scope mounts.

SKIP AHEAD

What Are the Different Types of Quick Detach Scope Mounts?

To be honest, there aren’t major differences between one quick detach scope mount and another. All scope mounts share some basic characteristics that make them very similar. However, quick detach scope mounts do have some variations.

Understanding these differences can be critical when choosing the proper scope mount for your optic and your rifle.

By and large, quick detach scope mounts are intended to be used on rifles that are fitted with either Weaver or Picatinny rails on the receiver. Sometimes, a rifle or shotgun that doesn’t have rails can be drilled and tapped to allow rail systems to be fitted so a quick detach scope mount can be used.

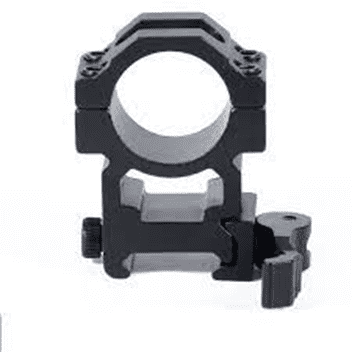

Split Ring Quick Detach Mounts

Split ring quick detach mounts look a lot like traditional scope rings. These types of scope mounts are typically sold in pairs.

Split ring QD scope mounts have some distinct advantages over other types. Some disadvantages may affect your decision on which type of quick detach scope rings to purchase for your rifle and optic.

Split Ring Advantages

The biggest advantage to using split ring quick detach scope mounts is the versatility this type of mount affords. Other types of QD mounting systems won’t allow you to customize the location of where the rings fit around the scope tube.

A split ring mounting system is easily fitted to any scope or any receiver mounting system regardless of the scope’s length and other accessories that may be attached.

Disadvantages of Split Ring Mounts

The split ring system doesn’t provide as much stability to the mount and the scope as single-piece QD mounts. Because the rings are not connected, they can move independently, which can seriously affect your scope, rifle accuracy, and consistency.

If either scope ring slips, moves, or is displaced, it will not hold zero when it is refitted to the rifle.

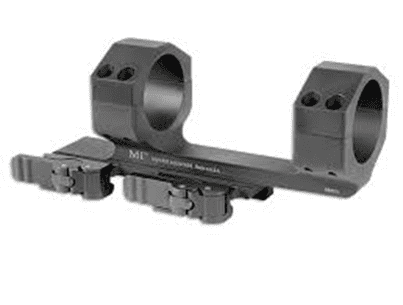

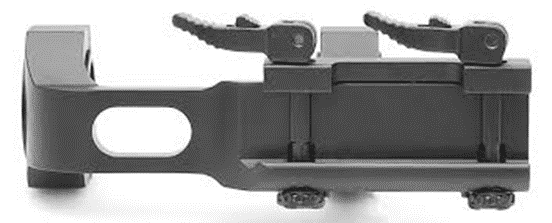

Single-Piece QD Mounts

As the name implies, single-piece quick detach mount systems feature a one-piece design that provides a much higher level of repeatability and stability to the scope mounts.

The single-piece design also simplifies the mounting and locking system. Single-piece QD mounts are available in various ring sizes, base lengths, and locking styles.

The Advantages of a Single-Piece Design

Single-Piece QD mounts tend to be more stable than split rings. Since the scope mount is a single piece of metal, the scope rings are always in the same orientation. This keeps the scope aligned with the mounting base.

If the rail system is properly aligned with the rifle or shotgun bore, the scope should return to the same position each time it is removed and refitted.

Disadvantages of SINGLE-PIECE Mounts

Many shooters point to the additional weight a single-piece scope mount can add to a rifle or shotgun. Even though the weight difference is minimal, it is important to some shooters under certain circumstances.

In addition, if you plan on moving your scope from one firearm to another, the alignment of the rail systems on the two guns must be identical to ensure that the scope returns to zero each time it is refitted.

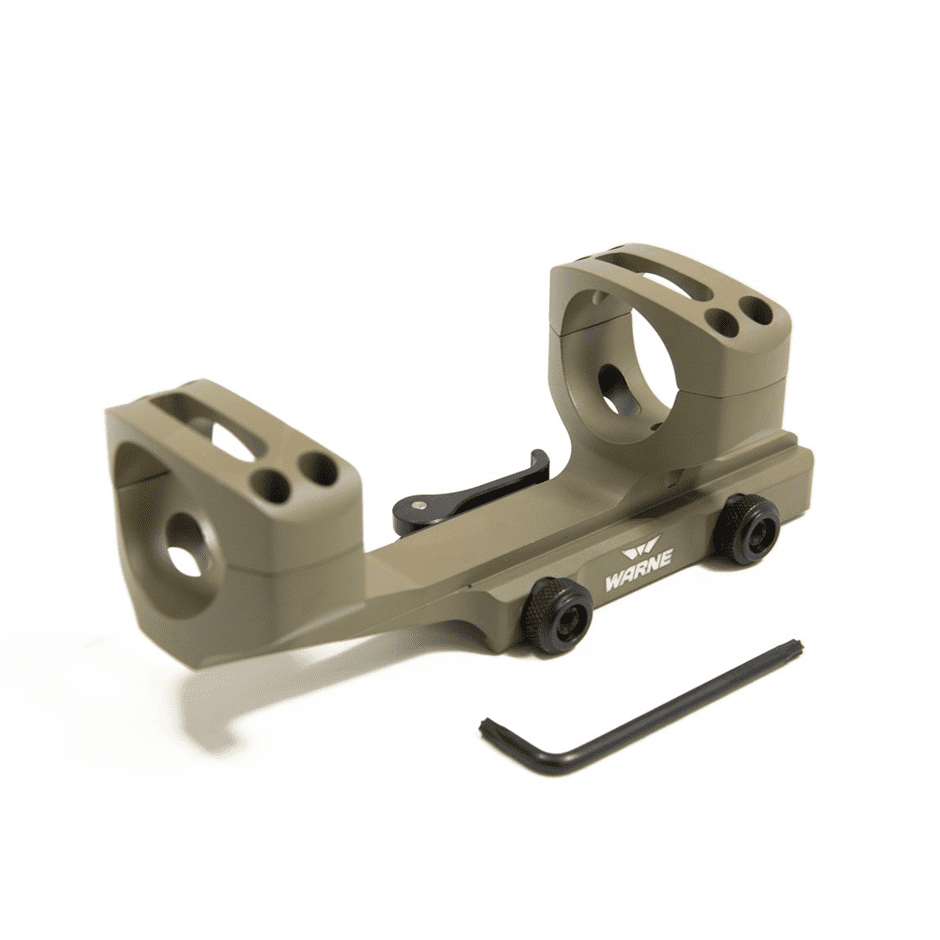

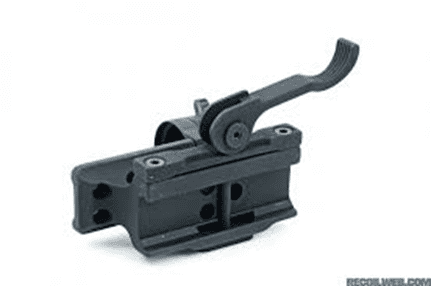

Cantilever QD Mounts

Cantilever mounts are a variation of a standard single-piece QD mount. Cantilever scope mounts are designed to allow a scope mount to be moved forward or backward to compensate for extremely long or short eye relief.

Some rifle receiver designs do not allow mounting a rail in the traditional location on top of the receiver. Some lever action guns pose this problem, as do some scout-style bolt action rifles.

Advantages of a Cantilever Mount

Cantilever mounts are extremely useful when mounting a scope on a rifle that doesn’t allow the placement of a rail in the traditional location on top of the receiver.

Lever action rifles have this problem and allow the scope mounts to be placed forward of the receiver but position the scope back in a more traditional location.

This is also an advantage of some styles of bolt action rifles.

Disadvantages of a Cantilever Mount

Typically, the lock and mounting base on a cantilever-style mount are shorter than those on traditional single-piece QD mounts. This can lead to problems with the stability and repeatability of the mounting system if the tolerances on the locking system are not tight.

Great care must also be used to ensure that the locking system is properly positioned and tightened.

Quick Detach Locking Systems

Quick detach scope mounts also differ in the way the scope mounts lock to the rail on the rifle.

The quality of the locking system is also critical to ensure that the mount and scope remain stable and firmly affixed to the rifle in the correct orientation. Various manufacturers use several different locking mechanisms.

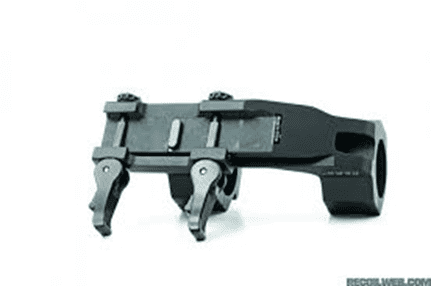

Single and Double Lever System Locking Mechanisms

Lever system rail locks are popular because the scope and mount can be dismounted from a rifle and reattached to another firearm.

Typically, level systems operate using a cam design that pulls the mounts tight onto the Weaver rail or Picatinny rail when the lever is thrown to the locking position.

Better QD mounts will have an adjustment feature on the lever system that allows you to adjust the cam’s tension on the base. This allows customizable lever positions and a range of torsion options on the mount.

This style of quick-release mount can be very stable if the machining and the tolerances are tight and the structural integrity of the materials is high quality.

Advantages and Disadvantages

I prefer the double-lever system over a single-lever and cam system. A double-lever system puts pressure on the front and back of the quick-release mount.

Single-lever systems usually center the cam and pin on the mount, which can act as a pivot point if the tolerance is not close and the torsion on the cam lever is not set tightly enough.

I am also always concerned about the quality of the materials used in any product that relies on tension and torsion to maintain settings. Vibration and recoil are a constant worry on any quick detach mounting system.

Lever and cam systems tend to be more prone to vibration and shock than other styles of locking systems.

Screw Type Locking Systems

The alternative to a cam and lever locking system is a threaded screw system. These also come in double and single varieties.

In addition, you can find threaded screw locking systems with many different types of screw heads, from thumb screw setups to screws that require proprietary tools to turn the locking screws.

My first concern with many of the threaded screw locking systems is whether they qualify as quick detach scope rings? If you must find a tool to loosen the screws to remove the scope and rings, it isn’t much different than taking a traditional set of scope rings off of a rifle.

Screws and Tools – Which to Choose?

Regarding QR scope rings, I prefer those that use an Allen head screw to lock down the scope mounts on the rails.

There are several different options available. Finding the one you prefer can be challenging.

These are my thoughts on the different styles of locking screws commonly available:

- Phillips or straight slot screws – I shy away from anything that requires a screwdriver to tighten or loosen. In either case, the screw heads are more prone to damage, making taking them on or off a problem.

- Hex Head Screws – These are better than Phillips or straight slot screws, in my opinion, but not by much. In many cases, the hex bolt corners can become rounded, making getting enough tension on the screw difficult. Many manufacturers use a hex head screw with a slot or Phillips head, which can further weaken the hex head configuration.

- Thumb Screws – I avoid thumb screw mounts with a passion. Getting enough tension on the screws to secure the mount is almost impossible. If you do get it tight enough, chances are, you won’t be able to unscrew it without a pair of pliers.

- Allen Head Screws – If I am shopping for a quick detach scope mount that uses screws on the locking mechanism, I will almost always opt for the one with Allen head screws. Allen wrenches are small and easy to pack into a range bag or a pocket-sized cleaning kit, so they are always handy. Allen head screws are not prone to damage like other screw heads and can be easily tightened to provide a secure mount.

- Proprietary Screw Types – Using a propriety attachment system doesn’t make sense in my book. If I am hunting, I want to carry as little extra weight as possible and lugging a tool that is only good for one purpose seems to be at cross purposes. Invariably, I can’t find the proprietary tools when I need them, adding to what is probably already a frustrating situation.

Pay Attention to THE Material Quality OF the Locking system

Quick-release scope mount systems are subject to a lot of stress and abuse. The shock of related recoil and transportation can doom many QD scope rings made from inferior materials.

When choosing a QD mount for your rifle and scope, you should put higher-quality materials near the top of your shopping list.

Some imported quick detach scope mounts shave costs by using cheaper screws that may not have the structural integrity needed to provide adequate tension and to withstand recoil.

A stepped screw on your QD scope mount or the QD levers can end a hunt or target shooting session early.

Other Considerations When Choosing a Quick Detach Scope Mount

Quick detach scope mounts come in various styles from many manufacturers, and at such different cost points, deciding on the best QD scope mount can be challenging.

Along with deciding which style of quick detach scope mount is best for you, here are some other considerations to factor into your decision:

Quality of Construction

Any part of an optics system depends on the manufacturing quality. A scope mount is no different, and a QD scope mount is especially dependent on the attention to detail that produces a quality product.

You want to ensure durability in your scope mount and provide a rock-solid base for your riflescope.

Materials

Most QD scope mount bases are made of aircraft-grade aluminum, which is a great choice. The material is excellent for a quick detach mount because of its strength, rigidity, and lightweight.

However, some offshore manufacturers use much lower quality aluminum alloys that are case and not CNC machined. These types of QD scope rings should be avoided if possible.

Several manufacturers still make all-steel mounts if you prefer steel for your quick detach mount. On some larger caliber rifles, steel is a better choice than aluminum.

A steel quick detach mount can add a few ounces of extra weight, but when you are dealing with heavy recoil loads, the extra weight may be a bonus.

The Rings

I have focused mainly on a quick-release scope mount’s bases and locking mechanisms. One other very important piece of this equation is the scope rings themselves.

You can have the strongest base and locking mechanism available, but if the scope rings are inferior or are not proper eye position ready, the scope mounts are virtually worthless.

Before choosing your quick-release scope mount, be sure to accurately measure the height you need to ensure that the scope is properly positioned for your eye. This also includes purchasing the correct QD mount to ensure that the eye relief on your scope mounts can be adjusted correctly.

One place that many shooters forget to measure is the clearance needed for the objective lens of their riflescope tube. A larger objective lens diameter requires a high mount to allow the lens housing to clear the barrel. This may be a problem with some QD scope mount installations.

Ring Size

You can purchase a quick-release scope mount with all of the most popular ring sizes. QD rings are available in one-inch, 30-mm, and 34-mm sizes to accommodate almost any scope on the market.

Before you start shopping, be sure of your riflescope tube size. Buying the wrong size QD rings can be embarrassing.

The two most popular sizes of scope tubes in the U.S. are one-inch and 30 mm. Almost every manufacturer offers their QD scope mounts in these most popular sizes.

Your QD mount should match the diameter of your scope tube precisely to avoid damaging your scope and to ensure that you can be as accurate as possible.

Scope Ring Screws

My preference for any QD mount is as many screws on the scope rings as possible. Ring screws are another possible point of failure on any mount, not just a QD mount.

Most of the scope mounts that I use have at least four ring screws on each ring. The more ring screws, the more the load is spread, which decreases the chances of the ring screws becoming loose.

You can find rings with two screws, four screws, six screws or even eight ring screws per ring.

Most QD mount manufacturers will specify a torque setting for the ring screws on their QD mounts. It is important to follow these recommendations carefully to ensure that QD rings are not over-tightened, which can damage your scope.

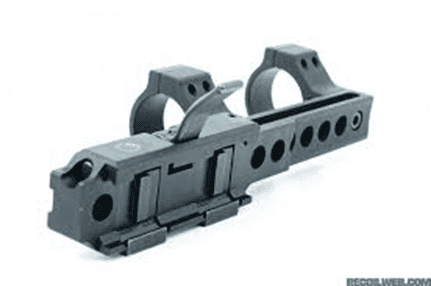

Can I Still Use My Iron Sights with a QD Mount?

Many manufacturers make models of a QD scope mount that allows the shooter to access the iron sights on the rifle. Even one-piece and cantilever mounts are available that have openings in the base to allow iron sights to be seen.

Accessing your iron sights while a scope mounts on the rifle often requires a high mount which can cause problems with eye position and, in some cases, eye relief.

Some shooters argue that a QD mount doesn’t need to allow access to your iron sights. They argue that if the scope fails, the QD scope mount allows you to remove the scope mounts to access the iron sights easily.

I really don’t have a preference either way. This is a matter of personal preference in most cases.

I Need Extra Eye Relief

If you need extra eye relief for your scope mounts, you should consider an extended cantilever style of QD scope mount. The extended cantilever designs can offer as much as an additional 1.75 inches of eye relief.

An extended cantilever QD scope mount is a good solution if you need to mount your scope to gain some distance from your shooting eye.

You may find these specialized quick-release mount options in an extended cantilever design one of the highest-priced options. The extra length requires designing the QD base to higher standards to withstand the extra stress and loads on the QD scope mount base.

The Downsides to a QD Scope Mount

For all the perceived advantages, there are some disadvantages to using a QD scope mount on your rifle. Most shooters choose a QD mount for the convenience they offer. It is easier and quicker to mount a scope with a QD mount.

This is a perfectly acceptable reason as long as you understand the problems that may occur with these kinds of scope mounts.

Complexity

A QD mount adds another level of complexity and moving parts to your rifle. This adds failure points that may overshadow the convenience of the quick-release options. Any scope mount must provide a rock-solid connection between the rifle and the scope to ensure that it will hold zero once properly adjusted.

Moving Parts That Move When They Shouldn’t

I have witnessed far too many shooters frustrated with a rifle and scope that couldn’t be adjusted to give accurate results. Most of the time, the problems can be traced back to the scope mounting.

Either the scope and rings were improperly mounted on the rifle, or the scope mounts failed to secure the scope. This is a constant problem with cheaper quick-release mounts.

Often the best solution to these problems is to pay the additional cost to purchase a higher-quality mount for your scopes and rifles. I am not saying you must pay an ultra-high cost, but in the long run, the additional cost of a quality mount for your scopes and rifles is a good investment.

My Rifle Doesn’t Have Rails. Is There a Solution?

If your rifle isn’t equipped with Weaver or Picatinny rails, you can add accessory rails that will allow you to mount a QD mount.

Picatinny rail mounts are the choice for many shooters over the older Weaver-style rails. When an accessory rail is properly mounted to a rifle, it is safe to mount the heaviest QD mount.

The one caveat that I will make about adding Picatinny or weaver rails to a rifle concerns the gunsmithing required to do the job properly.

Drilling and tapping a rifle receiver and ensuring that the rails are properly aligned with the bore takes experience and the proper training. This is not a job for the average shooter and should be left to a trained gunsmith.

My Rifle Loads and Ejects from the Top – Can I use a QD mount?

Some rifles loading and ejection system don’t work well with a standard receiver-mounted scope.

In these cases, employing an offset scope mount may be necessary to allow clearance for the loading and ejection systems to operate properly. If the offset mount has a Picatinny rail, it should work with a QD mount. You may run into problems with eye relief on some offset scope mounts.

In some cases, adding a Picatinny rail to the rifle may be necessary to allow the offset mount a connection point. This can lead to additional problems and costs.

The more things you add to the top of your rifle, the more the center of balance changes, the heavier the rifle becomes, and the more cost you have in the scope mount system.

Can a QD Scope Mount Really Re-Zero?

A good mount will often re-zero reliably after being dismounted and remounted. The major factor in any zero guarantee is the quality of the mounting system, and the care used when the mount and scope were installed in the rifle.

The best scope and mount available will never perform properly if the mounting was done poorly.

My Recommendations for Choosing a QD Mount

In the end, if I choose a QD mount for my rifle and scope, I use some basic criteria to make my selection.

In general, I will shop for known manufacturers with a good reputation. I avoid imported mounting systems because of the unknowns, such as the quality of materials, machining, and tolerances.

I prefer one-piece mounts over two-piece systems if my rifle is compatible. I also prefer two-piece rings with at least 4 ring screws per ring.

Making Your Choice

As you shop for a QD mounting system for your scope and rifle, I hope the insights I have provided give you some direction that helps you find the best solution for your scope mounting project.

It really doesn’t matter if you are mounting a long-range precision scope or a simple red dot, the basic selection criteria are the same. Choose quality, and you will almost always be rewarded with consistent and precise operation from your scope, mounts, and rifle.